Manufacturing Process

Alimac has produced self-adhesive tape carry handles since 1990.

Over the years, it has improved the manufacturing process, thus reaching the highest levels of technology and service worldwide, also focusing on top-quality products and production control.

Over the years, it has improved the manufacturing process, thus reaching the highest levels of technology and service worldwide, also focusing on top-quality products and production control.

Some of the most famous brands in fast moving consumer goods are Alimac customers. Their trust in us is the evidence of Alimac quality.

The Alimac manufacturing process numbers five main activities:

The Alimac manufacturing process numbers five main activities:

- • Components production

- • Coating process

- • Slitting (Cutting) process

- • Insert ( or “Inlay”) production for prelaminated tape carry handles (Alimac German plant)

- • Coupling phase for prelaminated tape carry handles (Alimac German plant). The film (= backing) manufactured in Italy is coupled with the insert (inlay) manufactured in Germany, customized (artwork in 8 colours as requested by the customer) and exported all over the world.

The 5 strengths of the Alimac manufacturing process:

- • Core-business is 100% tape carry handles. All efforts in terms of technologies, human and financial resources focus on tape carry handles for handling solutions.

- • The curve of experience is very long as Alimac was one of the “first movers” in the international market. Our case studies give us the best practices of this business. We moved the considerable experience gained to the in-house manufacturing of handle applicators under the Mactec brand.

- • Selection of raw materials. Years and years of experience in the market enable Alimac to select only the best raw materials.

- • 100% in-house strategic manufacturing. Alimac manufactures in-house the strategic parts and the tape carry handles. Alimac has made significant investments in equipment, production plants, R&D and processes so that it has the governance of the whole production process.

- • Strict quality control. Every day, more than 150 tests are carried out in the Italian and German plants. An expert team conducts 49,500 quality tests a year to deliver product excellence.

100% Strategic Production Control

Alimac manufactures 100% in-house. All the strategic parts, components, procedures, tests, controls and expertise are carried out by Alimac in its plants in Italy, Germany and China.

The advantage is evident - all the manufacturing process is under strict control at every step to ensure product excellence.

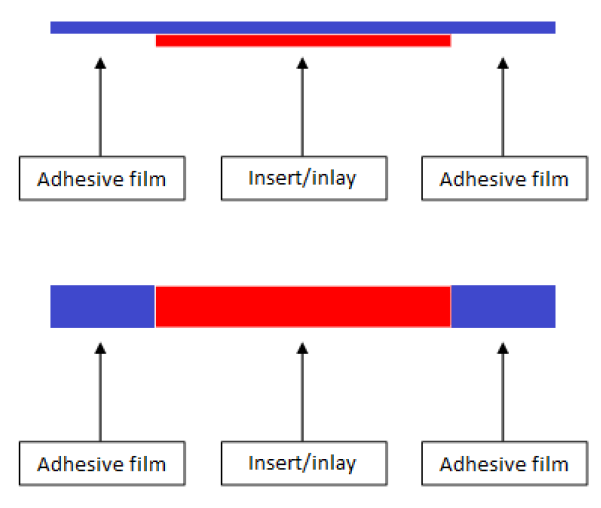

The tape carry handle is made of three fundamental components:

The advantage is evident - all the manufacturing process is under strict control at every step to ensure product excellence.

The tape carry handle is made of three fundamental components:

Backing

The backing (also called “film”) is the base of the Alimac tape carry handle.

It is the strip where the adhesive layer and insert (or inlay) are put. Alimac backing usually is made of mono-oriented polypropylene (MOPP), excellent in stretching without breaking.

It is subject to longitudinal traction and other stresses and daily movements.

During the manufacturing process, the film looks like a large, flat sheet running unrolled on the machine reels.

It is the strip where the adhesive layer and insert (or inlay) are put. Alimac backing usually is made of mono-oriented polypropylene (MOPP), excellent in stretching without breaking.

It is subject to longitudinal traction and other stresses and daily movements.

During the manufacturing process, the film looks like a large, flat sheet running unrolled on the machine reels.

Advanced electronic devices scan the surface seeking any kind of imperfection.

Alimac is an environmentally-friendly company; film with flaws during production is recycled in an appropriate machine producing new resin granules, which are re-utilized to produce new film. No waste, no pollution.

Alimac is an environmentally-friendly company; film with flaws during production is recycled in an appropriate machine producing new resin granules, which are re-utilized to produce new film. No waste, no pollution.

The final product of this process is a reel of excellent backing (film), ready to start the second phase - coating with the adhesive.

Adhesive Hot Melt

Alimac uses “hot melt” adhesive, very useful for industrial uses and able to resist external factors (temperature, humidity, etc).

The adhesive is produced in Alimac plants.

The adhesive is produced in Alimac plants.

Once the adhesive has been produced, some samples are analyzed by the Quality Dept. to verify the level of stickiness and viscosity. Some devices measure both these parameters electronically and mechanically.

Alimac is able to produce different kinds of adhesive for the different application needs and customers’ requirements.

Alimac adhesive usually holds up to 21 kg of packaging but it can hold up to 30 kg in special projects for industrial applications.

Alimac is able to produce different kinds of adhesive for the different application needs and customers’ requirements.

Alimac adhesive usually holds up to 21 kg of packaging but it can hold up to 30 kg in special projects for industrial applications.

Insert / inlay

The inlay is the central part of the tape carry handle. It is also called “handle” or “label” (not to be confused with the label-tape carry handle, an innovative type Alimac tape carry handle).

Alimac designs the artwork with the customer and considers all the aspects related to the product image.

Alimac designs the artwork with the customer and considers all the aspects related to the product image.

The insert has two important functions:

- • Hold. It simply prevents the hand from coming into contact with the adhesive.

- • Marketing. It is an innovative marketing tool as it is printable. It makes excellent product visibility and more powerful on-pack communication possible.

Alimac has four types of insert / inlay:

- • Paper Inlay: is a strip of paperboard that can be printed depending on the customer’s requirements - logo, slogans, sale promotion, QR code and barcode.

- • Mono-oriented Polypropylene Inlay. This can be coloured or completely transparent.

- • Foamed Inlay with a thickness of 1 or 2 mm makes the Alimac tape carry handle more comfortable.

- • Coupled combinations, such as paper + foam.

Here is an example of our artwork production

en

en  it

it es

es de

de fr

fr zh-hans

zh-hans ru

ru