Tape carry handle Quality Test

Alimac has constantly improved the quality of production achieving standards of absolute excellence worldwide.

Alimac carries out tests to check product quality thus ensuring the safest hold. They are:

Alimac carries out tests to check product quality thus ensuring the safest hold. They are:

- • international standard tests. These follow the official guidelines and parameters of international organizations such as ASTM and ISOEN.

- • internal tests set up by Alimac under specific criteria.

Alimac Tests are implemented on the production line and in the laboratory and can be grouped into three main types:

1. Sample tests

Alimac implements sample tests on the production line. They are conducted on both components and the final product.

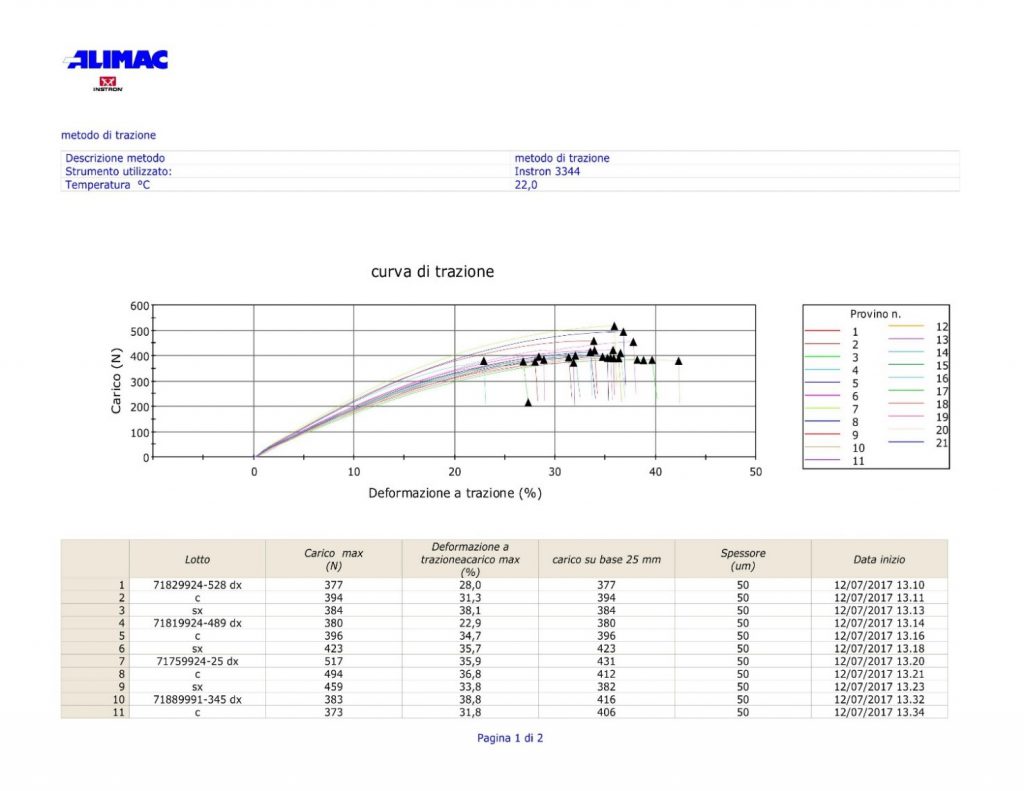

An example of a sample test is given below. The check is on tape carry handle deformation under a traction force:

An example of a sample test is given below. The check is on tape carry handle deformation under a traction force:

2. In-line automatic checks

In addition to sample tests, automatic checks are implemented on the production process and final product every day. Some of them are:

- 1. process temperature

- 2. ingredients and quantity

- 3. adhesive viscosity

- 4. thickness of film and adhesive

- 5. …………

Alimac tests on the final product are the:

- 1. total length of the tape carry handle

- 2. length of the individual pre-laminated tape

- 3. …………

All the results of automatic tests are always recorded.

Every day, Alimac makes at least 100 tests in the Italian production plant and 50 in the German plant for a total amount of 150 tests per day. Considering 330 production days per year, Alimac conducts 49,500 tests per year, not to mention the ones carried out in China for the Asian market.

Every day, Alimac makes at least 100 tests in the Italian production plant and 50 in the German plant for a total amount of 150 tests per day. Considering 330 production days per year, Alimac conducts 49,500 tests per year, not to mention the ones carried out in China for the Asian market.

Alimac carries out 49,500 quality tests a year.

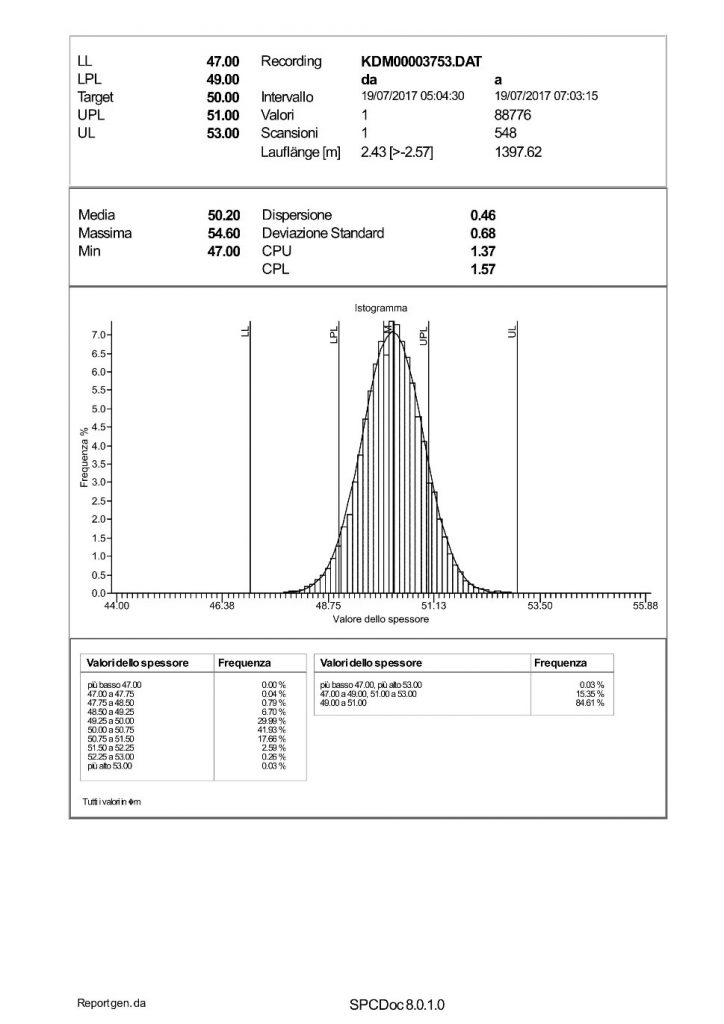

Here is an example of the tape carry handle thickness control, where 99.97% of the values are in the right range:

3. Laboratory Tests

These are:

- 1. control requirements

- 2. analysis of materials

- 3. simulations: - endurance tests and “accelerated usage” tests, where daily movements and stresses are reproduced in a short time.

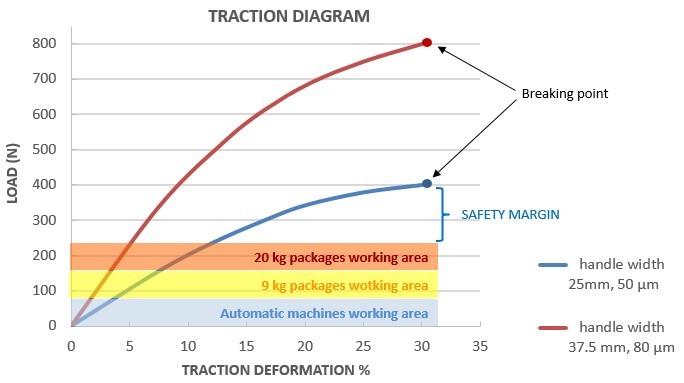

A traction diagram of the 25 mm (blue line) and 37.5 mm (red line) tape carry handles is shown below.

As we can see, here the 25 mm Alimac tape carry handle is dealing with a 9 kg package, very common for end-consumers. The yellow band is the normal working area.

Considering the stress, the load is increased up to 20 kg (200 N); the Alimac tape carry handle continues to work perfectly.

The breaking point is reached at 40 kg (400 N). This is a considerable safety margin for a standard 25 mm tape carry handle applied to a 9 kg package.

As we can see, here the 25 mm Alimac tape carry handle is dealing with a 9 kg package, very common for end-consumers. The yellow band is the normal working area.

Considering the stress, the load is increased up to 20 kg (200 N); the Alimac tape carry handle continues to work perfectly.

The breaking point is reached at 40 kg (400 N). This is a considerable safety margin for a standard 25 mm tape carry handle applied to a 9 kg package.

en

en  it

it es

es de

de fr

fr zh-hans

zh-hans ru

ru