| Backing type: | MOPP |

| Thickness: | 50 µm |

| Total thickness: | 70 µm |

| Adhesion on steel: | 10 N / 25 mm |

| Adhesion on PE: | 5 N / 25 mm |

| Tensile strength: | 350 N / 25 mm |

| Elongation: | 30 % |

| Label length: | 150 - 400 mm |

| Handle length: | 250 - 1000 mm |

| Available colours: | Transparent |

BE DIFFERENT IN A CROWDED PACKAGING WORLD

WE CREATE VALUE FOR BRANDS THROUGH HIGH QUALITY INNOVATIVE HANDLING PACKAGING SOLUTIONS

We believe that packaging must always be innovative, functional, accessible, with “shop-ability”, environment friendly.

We work on that since 1990 and we still continue to do it.

In our solutions we merge practical, artwork, economic aspects.

We want to simplify the daily life of end-consumers, help our customers to create a preference for them and increase sales and loyalty.

We offer new perspectives in handling systems of packaging, “Be different in a crowded packaging world” is our motto.

We work on that since 1990 and we still continue to do it.

In our solutions we merge practical, artwork, economic aspects.

We want to simplify the daily life of end-consumers, help our customers to create a preference for them and increase sales and loyalty.

We offer new perspectives in handling systems of packaging, “Be different in a crowded packaging world” is our motto.

C 105 -Tradition making the Difference

Technical characteristics

Stockage

| Temperature: | 10 - 40 °C |

| Humidity: | 20 - 80 % |

Order quantities

Orders can be placed for these quantities or multiples:

| Rolls | 576 | 1152 | 1728 | |

| Spools | 48 | 96 | 144 | |

| Pallets | 1 | 2 | 3 | etc. |

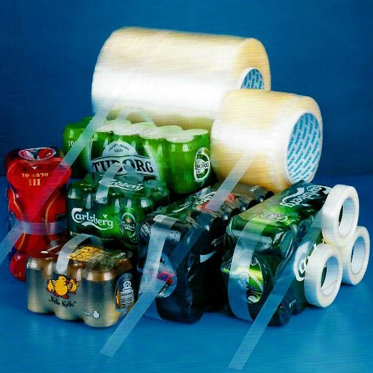

The “C 105 S” tape carry handle is a widely-used well-proven successful product.

It shows technical features that are highly suited for the preparation of adhesive handles for heavy packages. It shows suitable adhesion, special mechanical resistance and inertness to oxidizing agents.

It is made of a transparent strip of polypropylene (“backing” or “film”) with a paper insert.

The insert (also called “inlay” or “label”) is the non-adhesive area. It is separated from the film and has to be coupled by the handle applicator in real time, when packaging transits on the conveyor belt on the production line.

The Inlays are stacked in a clipboard, or “loading unit”, installed on the handle applicator.

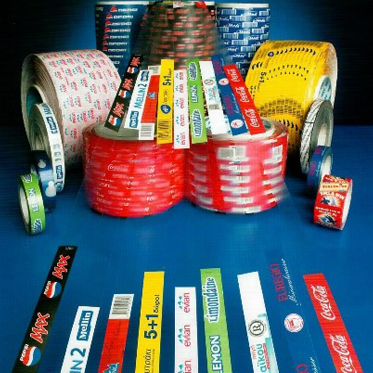

The Inlay is printable in up to 8 colours. Logos, payoffs, images, sale promotions, tables, bar code and QR codes can be printed. Everything can be reproduced and customized.

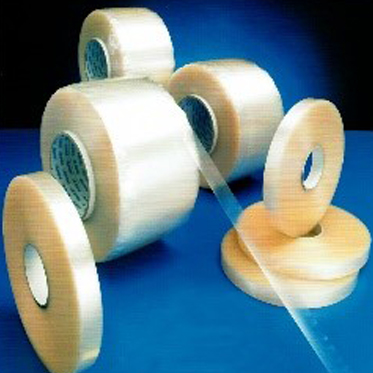

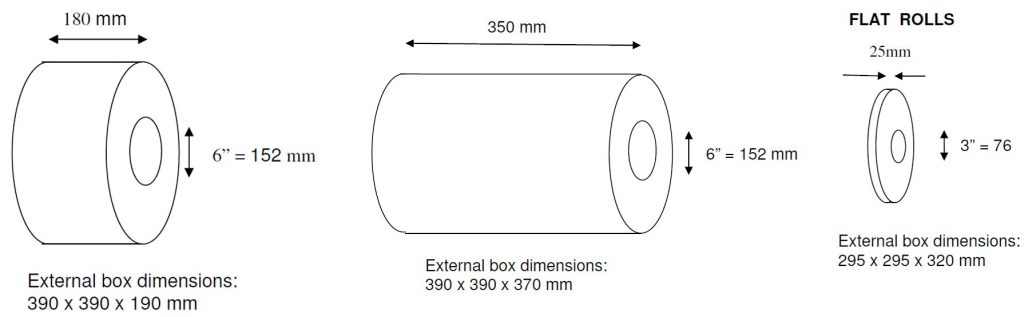

The transparent film is distributed in spools (for automatic application) or flat rolls (for semi-manual application).

The handle applicator is equipped with a roll holder; the film is unrolled little by little as every tape carry handle is first coupled and then applied to packaging and cut.

During application, it is important that the handle applicator aligns the insert correctly by centring the film laterally and longitudinally.

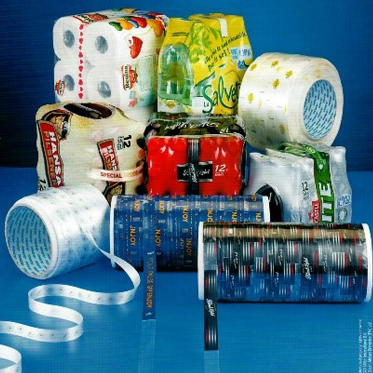

This type of tape carry handle is particularly useful when the customer has different packaging formats requiring different examples of artwork. It is sufficient to load the clip with a new example - no change of roll is required.

The standard handle tape width is 25 mm (other sizes 30-37.5 mm are available).

It is available in rolls of 650 m, 5,000 m and 6,500 m.

It shows technical features that are highly suited for the preparation of adhesive handles for heavy packages. It shows suitable adhesion, special mechanical resistance and inertness to oxidizing agents.

It is made of a transparent strip of polypropylene (“backing” or “film”) with a paper insert.

The insert (also called “inlay” or “label”) is the non-adhesive area. It is separated from the film and has to be coupled by the handle applicator in real time, when packaging transits on the conveyor belt on the production line.

The Inlays are stacked in a clipboard, or “loading unit”, installed on the handle applicator.

The Inlay is printable in up to 8 colours. Logos, payoffs, images, sale promotions, tables, bar code and QR codes can be printed. Everything can be reproduced and customized.

The transparent film is distributed in spools (for automatic application) or flat rolls (for semi-manual application).

The handle applicator is equipped with a roll holder; the film is unrolled little by little as every tape carry handle is first coupled and then applied to packaging and cut.

During application, it is important that the handle applicator aligns the insert correctly by centring the film laterally and longitudinally.

This type of tape carry handle is particularly useful when the customer has different packaging formats requiring different examples of artwork. It is sufficient to load the clip with a new example - no change of roll is required.

The standard handle tape width is 25 mm (other sizes 30-37.5 mm are available).

It is available in rolls of 650 m, 5,000 m and 6,500 m.

Available dimensions:*

| Tape carry handle height | Roll lenght (mt.) | Roll diameter | Pallet weight | Pallet dimensions | N° Rolls per box | N°boxes per pallet | Core diameter (inch) | Core height |

|---|---|---|---|---|---|---|---|---|

mm |

m |

mm |

kg |

cm |

|

|

" |

mm |

| 25 | 660 | 280 | 730 | 120x120x150 | 12 | 48 | 3 (76 mm) | 25 |

| 25 | 5000 | 330 | 490 | 80x120x170 | 1 | 48 | 6 (156 mm) | 180 |

| 25 | 6500 | 370 | 590 | 80x120x170 | 1 | 48 | 6 (156 mm) | 180 |

* Other sizes available upon request

Core information:

The above-mentioned data were taken from production samples and are not a warranty for the results of the applications. Therefore each application should be tested in advance.

Limitation of liability: excluding where forbidden by law, Alimac S.r.l. will not be responsible for any loss or damage depending from this Alimac S.r.l. product, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including but not limited to guarantee, contract, negligence or severe responsibility.

The previous guarantee and limited remedy and limitation of responsibility may be changed only by a written agreement signed by authorized officers of Alimac S.r.l. and seller.

Limitation of liability: excluding where forbidden by law, Alimac S.r.l. will not be responsible for any loss or damage depending from this Alimac S.r.l. product, whether direct, indirect, special, incidental or consequential, regardless of the legal theory asserted, including but not limited to guarantee, contract, negligence or severe responsibility.

The previous guarantee and limited remedy and limitation of responsibility may be changed only by a written agreement signed by authorized officers of Alimac S.r.l. and seller.

The Alimac-Mactec Integrated System is a competitive advantage and transfers added value to customers

1. A smart all inclusive solution | 2. Value added | 3. Interaction tape/machine |

4. System elements | 5. Turnkey solution | 6. Benefits |

Alimac tape carry handles - products

Request information now

Do you want find out more? Fill in the form and we will give you any kinds of information!

en

en  it

it es

es de

de fr

fr zh-hans

zh-hans ru

ru