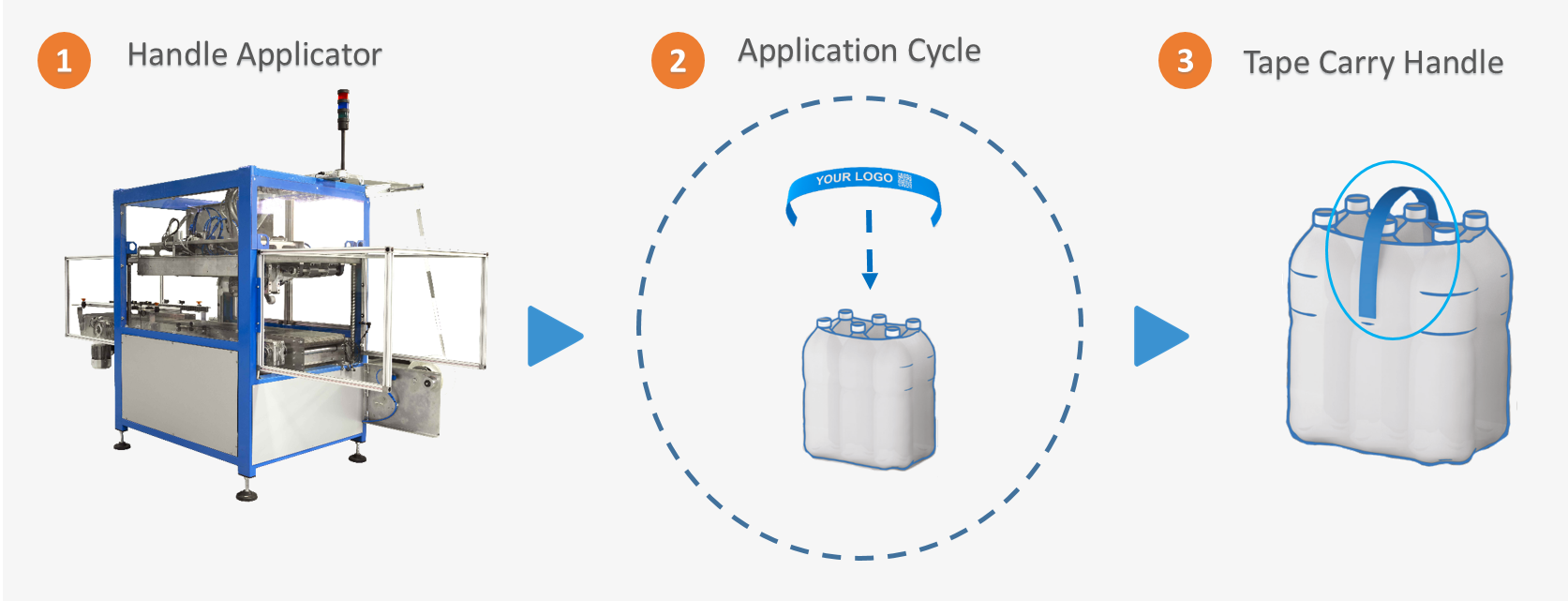

How it works

How it works?

Mactec Handle Applicators implement 2 technologies:

- • Pneumatic models. These work with a compressed air system. Designed for production lines with a capacity of up to 75 packs per minute (top application, single lane), they provide an excellent price/performance ratio.

- • Electronic models. These use modern servo-driven technology; the application head has one arm operated by two servomotors. This is the best solution for precision in high-speed applications (up to 100 packs per minute).

Mactec handle applicators maintain good space between the packs in transit, optimize the speed of packaging and synchronization. As a result they ensure:

- • Product line process continuity

- • Safe, precise and regular application

Latest generation software (PLC) manages the entire application process. It has a multilingual touch screen, is easy to use and allows fast format changeover.

en

en  it

it es

es de

de fr

fr zh-hans

zh-hans ru

ru